Metal Spraying

We have been carrying out metal spraying, also known as metallisation or thermal spraying, since 2020.

Thermal spraying is not a new concept but with more customers looking to repair parts or extend their operational lifespan, turning to the latest innovations in a established technology can provide proven cost-effective solutions.

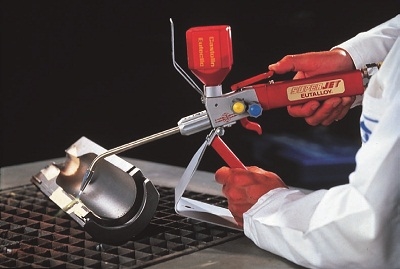

M J B Engineering has invested heavily in thermal spraying equipment from world leaders, Castolin Eutectic. The type of thermal spraying we undertake is flame spraying which utilises Oxygen and Acetylene to heat and propel the material being deposited onto the part.

Thermal spraying is ideal for restoring worn parts and providing wear or corrosion protection. It can be used on shafts, augers, fan blades, tooling and other types of equipment subject to wear, impact, abrasion or corrosion.

Most materials can be coated with this process including mild and alloy steels, cast iron, stainless steel, bronze and brass.

The process uses an atomised powder, which due to the range of alloys and materials available, can deposit soft or hard materials to the surface of the part to be coated – even plastics and ceramics can be applied. Each material has different properties that can be tailored to the specific application.

Thermal spraying allows us to make ‘cold’ repairs to shafts which have none of the detrimental effects on the shaft which traditional methods of welding would – there is virtually no distortion and the base metal remains unchanged metallurgically or structurally due to the part not rising above 250 degrees.

This allows us to reclaim worn shafts in a very effective and economical way. Seal areas subject to corrosion can be rebuilt with bronze or chromium alloys to provide very high levels of corrosion resistance. Likewise areas subject to friction or wear can be rebuilt with a low friction material for increased lifespan.