Mechanical Engineering

We cover all aspects of repair and maintenance engineering both onsite and in our workshop.

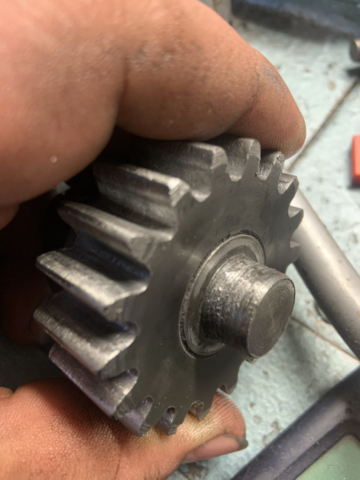

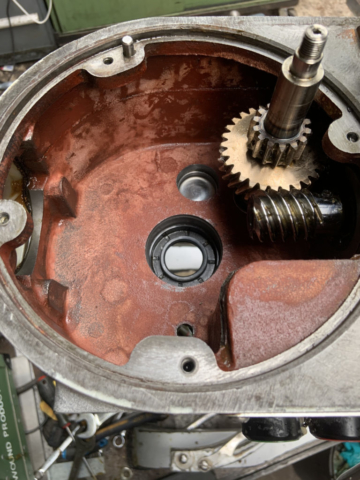

Routine maintenance such as bearing, chain and sprocket replacements are common works undertaken but we also carry out more niche services such as motor and gearbox rebuilding, shaft repair and retrofitting of modern control and drives on a variety of machinery.

M J B Engineering also offers Planned Preventative Maintenance programs to keep your equipment in excellent working order.

Workshop equipment includes a 30 ton hydraulic press, hydraulic pullers and separators up to 50 tonne along with bearing heating and dry ice shrinking facilities.

We have the equipment to dismantle seized, stuck or broken shafts, pins, bearings, gearboxes and many other components.

Usually our extensive arrangement of hydraulic pullers with up to 50 tonnes of force will remove most seized components, however we also have heating equipment and an exothermic lance for when the conventional methods fail.

Electric Motor Repairs & Rewinding

Whilst we troubleshoot and rebuild motors and pumps in-house, such as carrying out routine bearing and seal replacements, we work closely with a leading motor rewinder who can offer significant cost savings over replacing a motor whilst also maintaining high efficiency and reliability – offering a three year warranty on their work.

Common electro-mechanical services we can offer:

- Bearing Replacement & Bearing Journal Repairs

- Seal Replacement & Seal Area Repairs

- End Plate Sleeving & Machining

- Cast Iron Casing Repairs

- Machining of Motor Feet & Bases

Machining

Our machining capability includes turning, milling, horizontal boring and surface grinding. We also have several local machine shops that we work with to offer gear cutting, cylindrical grinding, open sided planing and jig boring.

We regularly manufacture replacement shafts, housings and other machined components for machines where the spare parts are no longer available or are uneconomical to purchase from the OEM.

We can produce internal keyways in sprockets, pulleys and bushes holding a large stock of metric and imperial broaches up to 18mm.

Shaft Repair & Reclamation

We are able to restore damaged shafts to their original dimensions and tolerances, which offers economical and fast turnaround compared to remanufacturing.

Damaged bearings seats, seal areas and keyways can quickly be rectified with minimal

Utilising arc welding, cold spraying or sleeve techniques, each shaft is individually assessed and the most cost-effective, reliable repair method chosen.

Our cold spraying techniques utilise flame spray equipment from world leaders Castolin Eutectic.

Thread Repair

We offer a wide range of thread repair techniques on threads of all sizes and forms – MJB Engineering can also remove snapped bolts and studs.

Common metric sizes of Helicoil™ are kept in stock, along with a large variety of BSW, BSF, BA, UNF & UNC. We also carry some solid thread inserts such as Keenserts®.

We can also carry out thread repairs to damaged external threads that can be chased. Damaged threads can be reclaimed after weld buildup and then re-machining to original tolerances.

Electro-mechanical Services:

- Routine Motor Condition Inspections

- Laser Shaft Alignment

- Vibration Analysis

- Troubleshooting of motor control systems.

- Replacement of failed components, drives and sensors.

- Retrofitting of modern controls and inverter drives for increased safety and efficiency.