About MJB Engineering

At M J B Engineering we use our accumulated expertise and specialised equipment to provide solutions to your engineering challenges. Our logical and adaptive outlook makes us ideal for companies in need of turnkey repairs, steel fabrication, on-going maintenance and complex engineering projects.

Our well-equipped workshop is situated in Brentwood, Essex; within 10 minutes of the M25, and we have been carrying out welding, engineering and associated works all over the UK for more than 10 years.

Our experience in multiple forms of welding is extensive. We cover all the common processes but also specialise in the repair of cast iron components, hardfacing of wear parts and reclamation of shafts.

Alongside our workshop and on-site welding services, MJB Engineering carry out regular planned maintenance, emergency breakdowns and de/commissioning works.

Our customers range from small businesses with less than five employees to companies who’s operations extend to a global scale.

A few of our qualifications and certifications are listed below:

- BS EN 9606-1 Coded Welding

- IPAF 3a & 3b Mobile Elevated Work Platform Certificate

- MPQC Safety Passport

- Counterbalance Forklift Certificate

- City & Guilds Medium Risk Confined Spaces Certificate

We serve primarily the heavy industry sectors – aggregates, cement, recycling and waste. This is where our years of experience in the field was accrued.

However, we also serve the local maintenance and repair industries and see a growing market in the food industry sector – typically large bakeries and food processing plants.

If we can help you please get in touch and I look forward to working with you in the future.

Bradley White – Managing Director

Our Equipment

Our welding equipment is of the latest innovative design and highest quality, being supplied by Lorch Schweißtechnik.

Turning

| Machine | Type | Capacity | |

|---|---|---|---|

| TOS | SN40C Manual Lathe | 400mm Swing 1000mm Centres 54mm Spindle Bore Accu-Rite Digital Read Out |

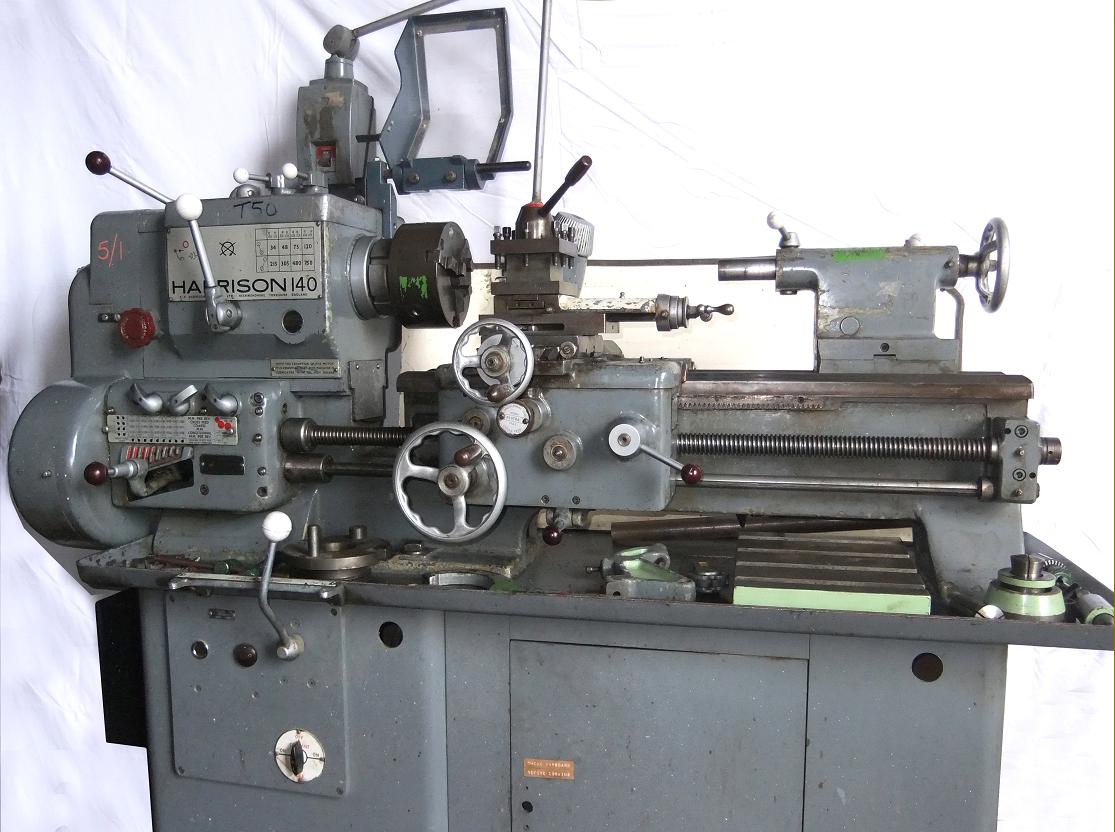

| Harrison | 140 Manual Lathe | 280mm Swing 600mm Centres 38mm Spindle Bore |

Milling:

| Machine | Type | Capacity | |

|---|---|---|---|

| Archdale | 18″ Production Mill | 20″ x 10″ x 14″ Capacity INT40 Spindle 3-axis Digital Readout |

Boring:

| Machine | Type | Capacity | |

|---|---|---|---|

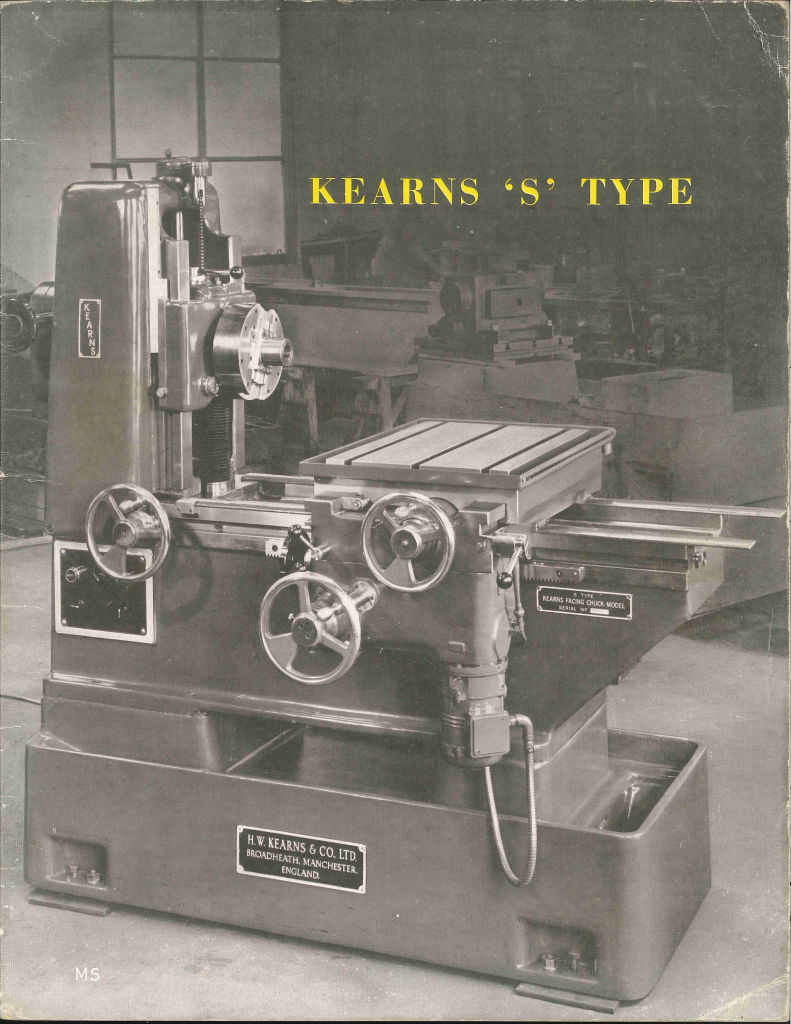

| Kearns | S-Type Optimetric Toolroom Borer | 12″ x 12″ x 12″ Capacity 8″ Facing Slide 3-axis Digital Readout |

Grinding:

| Machine | Type | Capacity | |

|---|---|---|---|

| JONES & SHIPMAN | 540 | 6″ x 18″ |

Fabrication Equipment:

| Machine | Type | Capacity | |

|---|---|---|---|

| Swift-Cut | CNC Plasma Table | 1250 x 1250mm 20mm Mild Steel |

| Bronx | Plate Roll | 8ft x 3/16″ | |

| Bronx | Ring Roller | 1″ x 4″ | |

| Kingsland | Hydraulic Punch | 60 Ton 1″ Hole in 7/8′ Plate | |

| Morgan Rushworth | Box Pan Folder | 1000mm x 1.5mm | |

| Blacker | Power Hammer |

Mechanical Engineering:

| Machine | Type | Capacity | |

|---|---|---|---|

| Enerpac | Hydraulic Press | 30 Ton | |

| Enerpac | Rams & Pullers | 50 Ton |

| SPX Powerteam | Hydraulic Bearing Separator | 30 Ton 10″ Diameter |

| Jones & Shipman | Inspection Centres | 24″ x 6″ Capacity | |